Micro-injection moulding (micro-IM) – moulding plastic parts that have a shot weight of less than 1g – has been around for over two decades. Andy Pye traces the development of the process to the present day.

Initially, in the 1980s, this technology utilized traditional injection moulding, but no dedicated machines were available until the mid-1990s. For very small shot weights, machines used to use plunger systems – similar to a syringe. These were used on specialist machines designed to produce components for specific markets. However, some of these specialist machines could cost up to £200,000, making entry into this market unviable for many moulders. In 2001, there were concerns about the higher pressures required for micro-IM (up to 40,000psi, compared with 20,000psi for traditional moulding) as well as handling, inspecting and packaging miniature components. At that time, it was also recommended that this moulding process should not be carried out on machines larger than 20 tonnes, because it was difficult to control and stabilise such small shot sizes, potentially leading to part damage and a lack of repeatability in the production process.

Design features

Now, the limit of what can now be moulded has reduced to parts as light as 0.0003g, with walls as thin as 0.0004in and dimensional tolerances to +/-0.0005in. At the IKV-Institute of Plastics Processing at RWTH Aachen University, thermoset micro parts with a shot weight in the area of 0.05 to 3.0g can be manufactured, which are advantageous in bio-medical applications.

Unlike conventional injection moulding, where manufacturability issues are considered in the product design phase, relatively little has been done for micro injection moulding, where the research community is still assessing the process capabilities. Open questions include how small components can be, and what is can the maximum achievable aspect ratio.

High aspect ratio components constrain its application. It is also quite difficult to design the cooling system because of the dimension of the mould, where the cavity and the ejection are only a few centimetres apart. This means that a temperature variation across the moulded part should be expected. One of the main goals related to the design of a micro mouldable component is the reduction of the shrinkage affecting shape stability in the form of induced warpage. Warpage occurs, due to the non-uniformity of the shrinkage induced by complex thermal variation inside the mould and its prediction is important for parts with relatively large area compared to their thickness.

The use of inserts becomes very important in micro injection moulding when, for example, micro cavities for microfluidic applications are realized and then fitted in the main mould body.

Another special feature is the system to measure the mould cavity pressure. Different methods are proposed to measure the cavity pressure, including a piezoelectric force transducer located behind the injection pin or a miniaturised quartz sensor to measure pressure directly.

Available machines

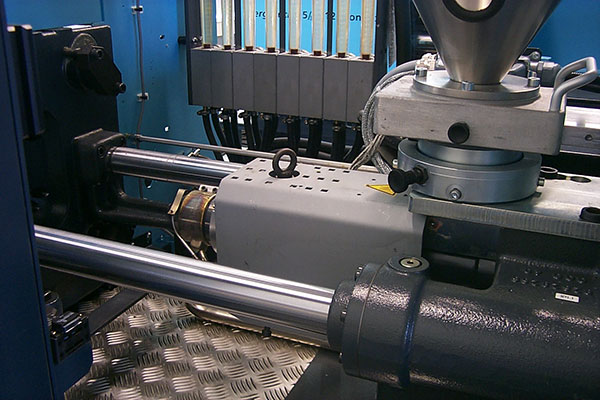

Currently, commercial micro moulding systems are produced by Ferromatik Milacron, Arburg and Sumitomo Demag as micro-injection units for conventional machines and Wittmann-Battenfeld, Babyplast and Desma as dedicated micro injection moulding machines.

The latest all-electric moulding machines have vastly increased precision, thanks to advanced direct drive technology. Very high levels of repeatability can be achieved while a specific 14mm screw design improves the dosing, which is critical in micro-IM and makes working with shot weights of between 0.1g to 1g more cost-effective.

According to Nigel Flowers, Managing Director of Sumitomo (SHI) Demag UK, using the 14mm screw, traditional 50- and 75-tonne IntElect electric machines from Sumitomo (SHI) Demag can be deployed. He says that the screw design is the smallest screw capable of processing standard plastic resins. Importantly, the 14mm screw enables users to limit the amount of material used by adapting nozzle body length and diameter to minimise residual time of material in the barrel. The 14mm plasticising unit contains around 8cm3 of plastic material at the screw. Traditionally, they would be used to run all sorts of different components with shot weights that were much larger than 1g, but the 14mm screw allows small shot weights and the fine control needed.

Market prospects

In 2012, the global polymer and thermoplastic micro moulding market – covering medical, automotive, electronics and telecommunications – was valued at just over US$300 million and industry commentators predict that the value of micro-IM will reach nearly US$900 million by 2020.

Nanotechnology is gaining rapid traction across a range of industries, including computing. In the future it won’t be just the size of components that matter, but the degree of engineering involved. Likewise, design advances in automotive, driven in part by rapid developments in microfluidics technology, are expected to boost demand significantly.

Despite more automation and smaller components, the process of micro-IM isn’t that dissimilar to creating larger parts. Shot-to-shot precision is where the main difference lies. Historically, micro-IMs would have used hydraulic machines, which meant dealing with variations in oil temperature and compressibility. Those drawbacks are removed from the equation with all-electric units.

After packaging and construction, electronics is the third biggest user of plastic components. The demand in electronics is driven by on-going innovation and advancements in nanotechnology, specifically sensors and circuits. As electrical, communication and information devices shrink and get lighter, so too does the size of the components contained inside. Moulding these parts, many of which are plastic and can house and connect the smallest processing chips, requires tremendous precision and durability. A major challenge is to offset the larger battery sizes that maintain power and make all other electrical components smaller.

In the automotive industry, increasingly complex vehicle electronics uses micro-injection moulding to manufacture connectors, gears and micro switches, as well as sensors. Germany holds a large amount of the European market for micro-injection moulding on account of the country’s lead position in automobile manufacturing.

In the global fibre optics market, micro-injection moulding is adopted for moulding gears such as micro connectors, ceramic holders and optics housing, as well as micro engines, micro drive control systems, and micromechanics rotators.

Parts handling

As well as offering repeatability and a stable production process, Micro-IM also requires a certain level of automation to ensure that the moulded items stay in optimal condition with regards part quality, hygiene – ensuring electrical components aren’t exposed to dust or particles and production efficiency. Cleanrooms might be used for if components are being supplied to the pharmaceutical, aerospace, military or biotech industries, but in the electronics sector this is less critical; unless the part is being surface treated or used as a decorative layer. Vacuums are often used to extract parts, to avoid contamination. Many machines have complex end-of-arm tooling systems to ensure parts are removed without damage.

References

- The Micro Injection Moulding Process for Polymeric Components Manufacturing; R. Surace, G. Trotta, V. Bellantone and I. Fassi; ITIA-CNR, Institute of Industrial Technology and Automation, National Research Council, Italy

- Less is more: Sizing up micro-electronic moulding trends; Nigel Flowers, Managing Director, Sumitomo (SHI) Demag UK

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

I want to build a bunch of toys to hand out at an event, but I need to produce a lot of them. It makes sense that I would want to use micro injection moulding! That seems like a great way to be able to make plastic parts without them being obviously moulded.

Micro molding maybe able to be use in the mobile phone camera Lens due to continue reduction on size and better perforrmance, Can you recomend equipment for molding of this type of Lens?