Coatings formulation chemists generally differ in their approaches to paint formulation, since, as individuals, personalities and problem-solving skills come in to play. In addition, if you are at one company for long enough, you may see that there is a preference for a certain supplier which may be the result of relationships formed long before your arrival. These are my suggestions in formulating coatings. There are really three main scenarios:

Coatings formulation chemists generally differ in their approaches to paint formulation, since, as individuals, personalities and problem-solving skills come in to play. In addition, if you are at one company for long enough, you may see that there is a preference for a certain supplier which may be the result of relationships formed long before your arrival. These are my suggestions in formulating coatings. There are really three main scenarios:

- Creating a brand new formula for a new application

- Modifying an existing formula to improve performance, etc.

- Using a new raw material

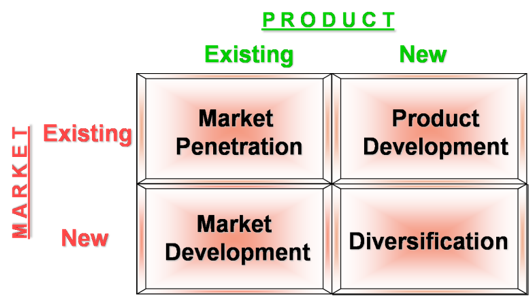

This isn’t too unlike Igor Ansoff’s Product/Market Expansion grid:

First steps for formulating paints

Coatings is a material science discipline and no different than any other science. You start with a literature search to understand the landscape. Use Prospector for starting point formulations (SPF), and search patents, applications and non-patent literature to review what exists to provide you a basis for your work. Your company may have an overall IP strategy that drives how and what you formulate, or/and you may want to stick with a trade secret approach. Regardless, it is important to understand the existing landscape including the competition.

Looking for some starting point formulations?

Prospector can help! Search hundreds of paint formulations from global suppliers. Filter search results by company, application, and more.

Search paint formulations

Creating a brand new formula for a new application

I suggest you rely on raw material suppliers’ SPFs to get an idea when creating new formulas. If this is really novel or you are inexperienced, that may be difficult. Talk with your mentor or an experienced colleague who can provide some insights and guidance. Generally, you work backwards to understand the performance requirements and substrates and formulate using materials that provide the performance within the required cost point. This usually dictates the resin/binder used as well as some of the prime pigments. Your company may be more open to the use of raw materials currently not in use, but you will have to defend their use as compared to what is purchased and in use.

In addition, it is rare that new technologies develop simultaneously globally. It is very likely if your geography isn’t leading the way, that there may be some published work on the emergent body of work you are contemplating.

Modifying an existing formula

In the second scenario, you need to have a thorough understanding of the raw materials available to you. As with a new application, unless it is a large-volume item, it is unlikely you will be able to get approval for a new material.

As an example, if an interior eggshell formula has poor uniformity over an inexpensive flat paint (enamel holdout), you might be able to replace amorphous silicates with micaceous and platy pigments to improve this result, but perhaps at a slightly higher cost, if you only address one pigment.

If an exterior paint has marginally-acceptable mildew resistance, you may need a blend of mildewcides, an additional additive, or zinc oxide. The addition of the reactive pigment may necessitate the use of a different dispersant to ensure shelf and heat stability.

Generally, you are looking to improve a property while preserving cost, or may be asked to reduce formula cost while maintaining overall performance. Formulation software is very helpful in this regard, once the libraries have been populated with the material data such as typical properties and price. Without it, generation of formulations is highly tedious and prone to accidental errors in calculations.

Using a new raw material

In the third situation, a supplier may discontinue a current raw material or your company may decide to consolidate raw materials. Look at the properties of the material to find an alternate. You will have to evaluate alternates as chemical offsets (equivalents), or functional matches for performance.

Some paint companies evaluate new raw materials of a certain type monthly. January may be the month to compare all new defoamers to incumbent defoamers, in some specific screening formulas.

As a final word of caution, always ensure that you fully understand your working parameters, related to performance, cost and process. It is a variance on the theme of cost, quality and speed. Product development hardly ever takes a short amount of time, so periodically checking with the product owner, your champion and others to ensure you are still properly aligned to the final goal is critical. And remember that failures are not only a learning experience, but sometimes result in the basis for a future innovation.

Further reading:

- How to Reformulate a Premium Ultra Matt Coating

- Ambient-Cured Latex Paints: How to Improve Performance

- The Challenges of Formulating Universal Colorants

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

Thanks Marc for the good information. Formulation software is also a good way to check formulation parameters and costs when replacing raw materials and developing new formulations. Besides Product Vision and Excel (two extremes) can you recommend any commercial software for paint formulation for use in smaller size paint companies?

Thanks, Peter

Thanks Mr Mark for these precious informations,

I wanted to ask you about the order to incorporate materials in paint production? which quantity shoud we put during the process of grinding or dispersion and adding complements

Thanks

Peter,

My apologies that I don’t always get notified when there is a response. Of course there are many commercial products from which to choose. Some are specific to formulation, and some are secondary to it. In the former, Formulator is a good platform but perhaps an overkill for a smaller company. Valdata offers a single-user free platform and there are others.

Accelrys used to have a part of their platform that could be utilized. Personally, I have created spreadsheets which is obviously time-consuming initially, but if you are a smaller company, it is doubtful that you have hundreds of raw materials. Then you just apply macros for VOC calculations, etc. Sometimes a RM supplier, in their desire to get you to use their products, may offer some software that can be utilized. Many years ago, when Ropaque OP-42 was introduced, R&H provided a (real) floppy disk that was set up to be able to add RM’s to adjust PVC, VS, etc.

There isn’t a simple answer as it depends upon the type of paint – water, solvent, etc. Also, in waterborne paints, you generally cannot grind/disperse pigments in the resin, but some are shear stable. That is why it is critical to talk with the raw material suppliers – resin, pigments and surfactants (dispersant, etc) are key. Another factor is the fact that what you do in the lab may not be reproducible in production. If you are making small batches, production may equal lab. But some companies produce 10-20,000 gallon batches (38-75,000 L). Look at the starting point formulations in UL Prospector Knowledge Base for examples.

Dear Sir

we are powder coating company for powder coating production , we are newly established for powder coating market needs ,But we have some troubleshoots in formula ,developments, if you are working in powder coating consultants then let us know to discuss in details ..

my best regards

fouzi mais

Hi,i am selaelo from SOUTH AFRICA.i am starting my paint company can you please assists with water based formulation of paint?

I didn’t see this question until today. I didn’t get notification so I am sorry that it took this long. There are many powder coating suppliers as well as consultants. I am sure that you have found one by now. If not, contact me and I will connect you.

Hi. Do you have any idea what it takes to start a paint company? I would be glad to help you, but you’re talking about something that will take a lot of time and a lot of money. At the very least, you need safety data sheets for the products that you make. You also need to determine who can supply you with raw materials to make the paint. You also need to know what kind of finishes you would like, as in flat, semigloss or eggshell. Interior or exterior? Water based or solvent based? Please contact me at [email protected] if you would like more information.