Original article date: Sept. 15, 2017

Updated November 2022

Introduction

A colorant is a concentrated dispersion of color pigment that can be added to a base paint to color that paint. A wide variety of colors can be made when colorants, each containing one specific color pigment, are combined. A line of foolproof colorants complies with several criteria to assure that a certain mixing ratio of colorants always gives the same color1. First, each batch of colorant must have the same color tone and color strength. Secondly, the color tone and color strength of each of the individual colorants must remain constant, even when the colorants are stored for a long time. A clever choice of raw materials is needed to assure a robust line of colorants.

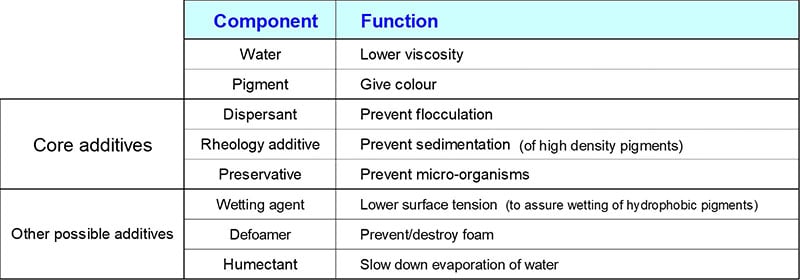

Composition of waterbased colorants

A colorant used for waterbased paints is most often a concentrated dispersion of one specific color pigment in water. Developers of waterbased colorants strive to create products that are compatible with a wide range of waterbased paint systems. These paints can be based on, for example, acrylic dispersion, polyurethane dispersion or alkyd emulsion. To assure broad compatibility, colorants must contain a low number of different components.

The presence of resin in a colorant might give compatibility problems with the binder system of the base paint. Therefore, colorants preferably do not contain resin. The desired colorants are often referred to as Resin-Free Pigment Concentrates (RFPC) or Binder-Free Pigment Concentrates (BFPC).

A modern waterbased colorant is zero-VOC, implying that the product is free of organic solvents.

A rheology additive is needed to prevent sedimentation of the pigment particles during storage. Use of a suitable rheology additive is especially important for colorants based on inorganic pigments, which have a high density. Aerosil® 200 is a fumed silica that is often used in waterbased colorants to prevent sedimentation.

As colorants become more and more environmentally friendly, they are more attractive to micro-organisms like bacteria, fungi and algae. Waterbased colorants must contain an effective preservative for that reason.

Preferably, wetting agents are excluded from colorants as wetting agents can give problems like foam, increased water sensitivity and worse mechanical properties. No wetting agent is needed when hydrophilic pigments are used.

Many waterbased colorants contain a humectant to prevent drying-in, caused by the evaporation of water.

Dispersant

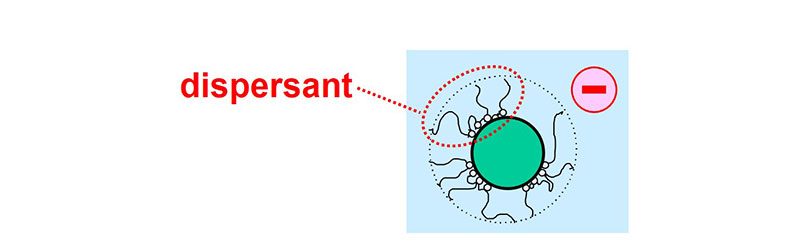

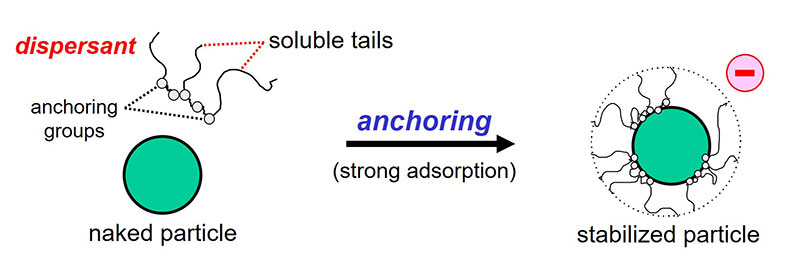

A key raw material in colorants is the dispersant2, an additive which assures stabilization of the separated solid particles against flocculation. In a foolproof waterbased colorant, the pigment particles repel each other by both electrostatic repulsion3 and steric repulsion4. It is said that such dispersants give electrosteric stabilization.

This dual-stabilization mechanism is needed to assure that the colorants are miscible with as many different waterbased paint systems as possible.

Preferably, a system developer uses as few as possible different dispersants for the whole range of color pigments in a line of colorants. This implies that the dispersant molecules must adsorb strongly at the surface of a wide variety of different pigments. A good dispersant for modern waterbased colorants complies with a few key criteria. First, the additive should be solvent-free. Secondly, to assure strong adsorption of the polymeric molecules at the surface of different pigments, the molecules must have a multi-anchor structure. This implies that each dispersant molecule has a variety of chemical groups that have a strong affinity for specific solid surfaces. These chemical groups, the anchoring groups, give strong adsorption, called anchoring.

Disperbyk®-199 is a polymeric solvent-free dispersant designed to stabilize a broad range of color pigments against flocculation in waterbased systems. The compatibility of colorants based on these types of dispersants is broad because the additives do not contain resin and they give electrosteric stabilization.

To develop or not develop colorants

The exact choice of raw materials and the amounts to use in a line of colorants depends on several factors like the pigments that are used and the types of paints that must be colored. The development of foolproof waterbased colorants that have constant color tone and color strength is a time-consuming and expensive task. Many paint manufacturers, therefore, choose to use ready-to-use colorants from companies that are specialized in developing and producing colorants, like Chromaflo Technologies.

References

- Article The CIELAB L*a*b* System – the Method to Quantify Colors of Coatings, Jochum Beetsma, 11 September 2020.

- Article Dispersants – The Understood Misunderstood Additive, Marc Hirsch, 10 September 2021.

- Article Dispersants for Electrostatic Stabilization, Jochum Beetsma, 21 November 2021.

- Article Dispersants for Steric Stabilization, Jochum Beetsma, 1 October 2021.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

Hello, Your article provides all my needed things. its helps me a plenty. will learn immeasurable factor from thins web log .you are doing nice. thanks for sharing your valuable ideas.

we need water based white materials and recipe

Dear Mr/Mrs Islam,

On the UL Prospector platform you can find a lot of raw materials, like white pigments, and starting formulations.

Greetings, Jochum Beetsma.

Dear Blend Colours team,

Thanks for reading the articles and for your positive reply.

Greetings, Jochum Beetsma.