Polyaryletherketone (PAEK) is a family of semi-crystalline thermoplastics with high-temperature stability and high mechanical strength. Plastics that fall within this family include:

- Polyetherketone (PEK)

- Polyetheretherketone (PEEK)

- Polyetherketoneketone (PEKK)

- Polyetheretherketoneketone (PEEKK)

- And the wonderfully named polyetherketoneetherketoneketone (PEKEKK)

The first significant commercialisation in this field was PEEK. Victrex of Lancashire, England, introduced PEEK resins commercially in 1981, when it was a unit of ICI Chemicals. The company went private in a management buyout in 1993. ICI also manufactured other high temperature thermoplastics under the Victrex trade name, notably polyethersulphone (PES).

The German plastics giant BASF AG exited the race to gain market share with PEK resins, ending its attempt to break into the market for polyketones, and stopping production and marketing of polyetheretherketoneketone (PEKEKK) resins. This left Victrex as the sole supplier of PEK resins in the world.

But growth rates for PEEK, increasingly used because of its high mechanical strength and chemical resistance in automotive, electronics, aircraft and medical applications, are around 10 percent. As a result, other suppliers have entered the market. Suppliers of PEEK now include Victrex (UK), Solvay Speciality Polymers (Belgium and US), Panjin Zhongrun High Performance Polymers (China) and Jida Evonik High Performance Polymers (China).

Recent developments

Reflecting this high demand for high-heat engineering thermoplastics, in 2015, Solvay announced that it would invest more than $85 million in expansions at its Specialty Polymers site in Augusta, Georgia and at a site already under construction in Panoli, India. Solvay's global PEEK capacity is now more than 2,500 metric tons with a new plant in Augusta, Georgia.

At the same time, Victrex also announced a return to double-digit growth and a £1.3 million grant from the UK government’s Regional Growth Fund to build a Polymer Innovation Center in a major new R&D facility in northern England.

These announcements were particularly timely because of the shortages of SABIC’s Ultem polyetherimide (PEI) high-heat resin, triggered in part by failure of capacity to keep up with demand.

PAEKs can be produced in two ways: the nucleophilic route and the electrophilic route. The nucleophilic route has the formation of ether linkages in the polymerization step. The electrophilic route has the formation of carbonyl bridges during the polymerization step.

They can be processed using all of the typical thermoplastic processes, such as injection molding, extrusion, compression molding, and transfer molding.

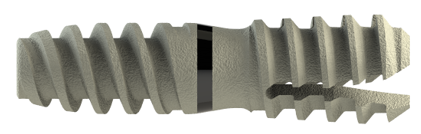

Due to excellent resistance to hydrolysis, the materials are being used in medical devices because they do not break down when sterilized. For example, PEKEKK is used to make surgical implants, such as artificial hips.

PEEK melts at a relatively high temperature (343°C), compared to most other thermoplastics. The San Francisco company Fictiv demonstrated for the first time the possibility of processing granular PEEK into filament form and 3D printing parts from the filament material using fused deposition modeling (FDM).

In January 2016 the German start-up Indmatec presented a PEEK filament for producing medical devices up to class IIa. With this new filament, it is possible to use the fused filament fabrication (FFF) method for different medical applications, including dentures.

PEEK is not traditionally a shape memory polymer; however, recent advances in processing have allowed shape memory behavior in PEEK with mechanical activation. This technology has expanded to applications in orthopedic surgery.

China approval for PEEK

Solvay has announced that Zeniva PEEK, one of the four products comprising its family of Solviva Biomaterials offered for use in implantable devices for spine, orthopedics, cardiovascular and dental applications, has successfully passed the biocompatibility testing at the China Food and Drug Administration’s Tianjin Medical Device Quality Supervision and Inspection Center. The inspection center at Tianjin is recognized as the most influential testing agency in the field of orthopedics in China.

Solvay’s family of Solviva Biomaterials has been commercially available in China since 2013. In addition to Zeniva, the product line features Veriva polyphenylsulfone (PPSU), which combines toughness with transparency and excellent biocompatibility; Proniva self-reinforced polyphenylene; and Eviva polysulfone (PSU), a transparent, biocompatible polymer that offers high strength and toughness.

All can be sterilized using all conventional methods including gamma radiation, ethylene oxide, and steam. These sterilizable products are available in grades for injection molding or extrusion, as well as stock shapes for machined components.

The test took over a year to complete and during this lengthy process, properties of Zeniva PEEK such as sensitization, intra-cutaneous toxicity, acute systemic toxicity, sub-chronic toxicity, genotoxicity and bone implant compatibility tests were examined to ensure biological safety in the human body.

PEEK medical devices

Zeniva PEEK boasts a modulus very close to that of cortical bone, plus excellent fatigue resistance and toughness. In addition, it offers advantages over metals, such as reduction of stress shielding, no heavy metal allergy or ion erosion, and has radiolucent properties which allow x-ray and CT scanning procedures without interference.

At the EUROSPINE 2016 exhibition, Solvay announced that its medical grade KetaSpire PEEK and AvaSpire PAEK polymers have enabled medical device pioneer, Shanghai Reach Medical Instrument Company, to develop a lighter, more ergonomic and highly cost-effective kit of reusable instruments for spinal surgeries.

“For decades, metal was the material of choice for medical instruments because conventional plastics could not deliver metal’s combination of high modulus, strong chemical resistance and compatibility with stringent sterilization methods,” said Xiaomin Huang, General Manager of Shanghai Reach. “Today, Solvay’s broad range of specialty polymers is changing that reality – not only by offering metal-like performance, but by also enabling the fabrication of more complex and integrated parts through cost-effective injection molding.”

Shanghai Reach’s innovative kit includes six reusable instruments: one rod bender, two pairs of distraction and compression pliers, and three awls. For the rod bender, the medical device-maker specified KetaSpire KT-880 CF 30 PEEK, a 30 percent carbon fiber-reinforced resin that delivers the high strength and stiffness necessary to bend implantable 5.5-6.0 mm titanium rods. For the pliers and awls, Shanghai Reach chose AvaSpire® AV 651 GF 50 PAEK, a 50 percent glass fiber-reinforced resin offering a cost-effective balance of strength, stiffness and dimensional stability.

Typically, these parts would be made from stainless steel. But Shanghai Reach’s goal was to reduce instrument weight by up to 70 percent for improved ergonomics, yet not compromise on mechanical properties or sterilizability.

Elsewhere, Instratek, a developer of medical devices for extremity surgery, has chosen Solvay’s biocompatible Zeniva PEEK resin to fabricate the radiolucent implant component of its innovative ToeTac Hammertoe Fixation System for the operative repair of hammertoe deformities.

Looking for PAEKs for your plastic formulations?

Prospector has listings for polyaryletherketone (PAEK) products from global suppliers. Find technical data, order samples and more now...

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

What about Gharda Plastics in India with materials like G-PAEK (PEK) and GAPEKK (PEKK)www.ghardaplastics.com/

They also produce PBI

Regards

Albert Jan

brillant article, Andy. Very informative, thanks!

This is a reply I think only of interest perhaps to Mr Pye. The first large scale use of polyarylenes was in fact for aircraft wire and the polymer was made by Raychem Corp in Menlo Park California, under the trade name Stilan. The wire was introduced in 1972 , and was covered by various slash sheets in Mil W 81044. The major customers were Boeing and Douglas who used it extensively on the 747 and DC10 ;and it was specified on numerous European and US military and commercial programs. It was qualified in the UK to DGS 344 which was the Navy low fire hazard equipment and multicore component wire standard.

It was reported to me that ICI introduced their PEEK polymer as a result of pressure from all the UK wire manufacturers, who saw their speciality wire market disappearing..

Subsequently, Raychem withdrew the product ( 1977) following the collapse of the commecial aircraft market following the second oil crisis. They sold off the process for making it to BASF but BASF as you say gave up on it.

The defiiciencies of polyarylenes are not widely publicised. The UV resistance is different for the different polymers and they are generally susceptilble to solvent stress crazing to a small range of solvents. The modulus temperature curve goes through some deep dips where the polymer undergoes a structure change.

Finally, the flex life is outstanding and the very low temperature performance is outstanding.

Great article on PAEK materials. I extrude these materials on a very regular basis and they are great to work. PAEK variants are also gaining acceptance as extruded components for replacing SS tubing and for micro-bore tubing applications in medical.

One bit of information, Solvay Specialty Polymers are no longer supporting the Proniva material.

Thanks for the article, it makes for an interesting read! We have been plating PAEK connectors for a few years now and the material offers many benefits over traditional engineered polymers.

Glad it helped. Can you share any information about your project?

HI Jonathan, I am Nikhil, an Analyst at Evalueserve India. I am currently studying the topic of specialty polymers and would like to speak to you to discuss some of the key aspects in this area.

It would be great if you could share your contact details to connect for a short discussion.

Hi, Nikhil. Please contact me directly at [email protected] so we can chat.

Thank you,

Andy Pye