According to the U.S. Energy Information Service, 40 percent of all US energy consumption is used for heating and cooling residential and commercial buildings. For homeowners, 25 percent of their average energy bill is for cooling. Considering these facts, consumers appreciate any efficiencies coatings formulators can offer.

Heat transfer mechanisms

Prior to considering how coatings can be engineered to save heating and cooling costs, it is instructive to examine heat transfer mechanisms: radiation, conduction, and convection.

Radiation

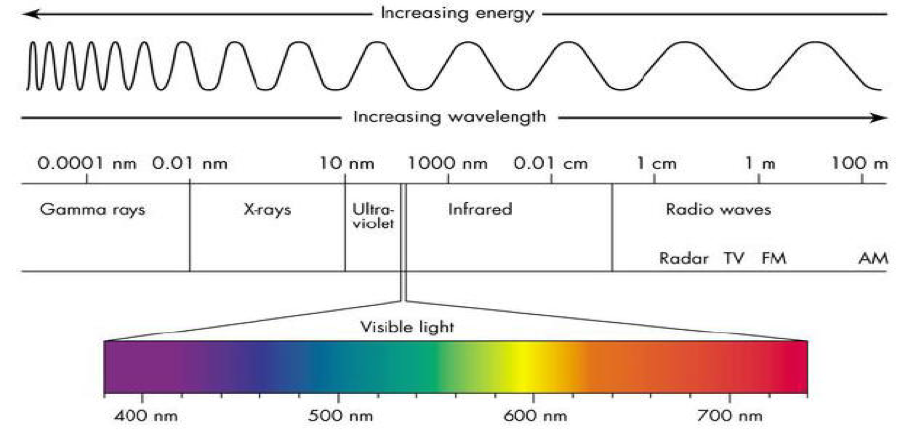

As figure 1 indicates, radiation is the emission and propagation of light energy in the form of rays or waves through space:

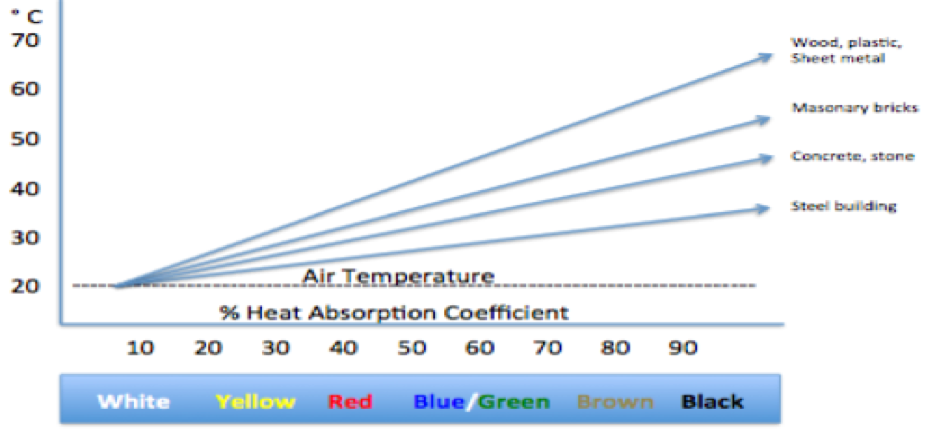

As figure 2 illustrates, pigments can absorb or reflect solar infrared energy based on their color. For example, if the pigment absorbs infrared (IR) energy (such as conventional darker pigments), we see heat build-up of the coated substrate. If the pigment reflects IR light (such as white and lighter colors), we see a lower increase in temperature.

To illustrate, the surface of a steel building at an ambient air temperature of 20° C will remain at about 20° C when painted white, whereas the surface will be about 35° C when painted black.

In summer, heat gain occurs through radiation, and in winter, heat loss occurs by conduction (solid-to-solid contact). Heat transfer by air movement is called convection (heat transfer via liquids or gases).

Emissivity is the ratio of radiation emitted by a surface to the radiation emitted by a black body at the same temperature. A material’s surface emissivity is a measure of the energy emitted when a surface is directly viewed. Generally, emissivity is measured indirectly by assuming 1- reflectivity, hence a highly reflective material has low emissivity.

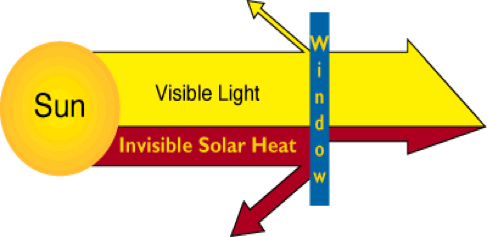

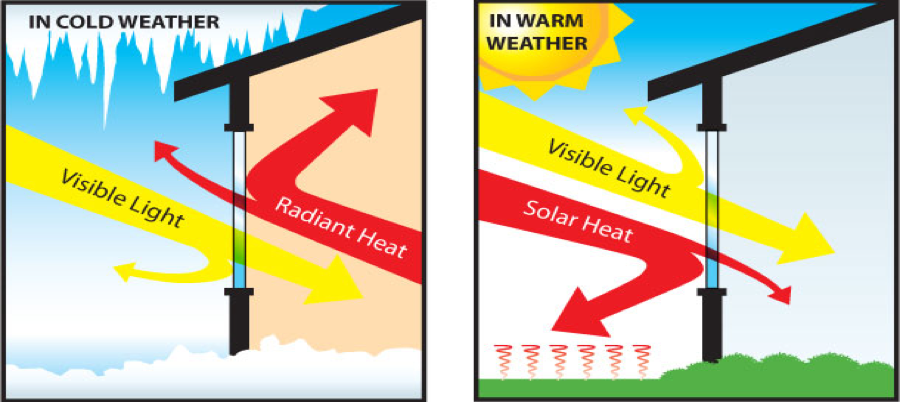

Figures 3 and 4 illustrate how a low emissivity layer in window glass can help save energy as a result of air conditioning. In the illustration, visible light is transmitted through window glass, but much of the IR heat in the form of solar radiation is reflected, due to the glass surface’s low emissivity layer.

Emissivity is a number between 0 to 1. For example, if a surface has emissivity of 0.1, it means this surface is reflecting 90 percent of the energy and conversely, the object will not absorb 90 percent of the energy in the form of heat. A mirrored surface may reflect 98 percent of the energy, while absorbing 2 percent of the energy.

On the other hand, a black body surface will absorb 98 percent of the energy and reflect only 2 percent, and thus absorb the energy in the form of heat. Among the variables that affect emissivity are geometrical, black body, the uniformity of the black body, temperature, wavelength, and emission angle.

Heat conduction and convection

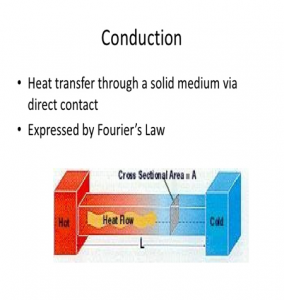

Conduction is the transfer of heat between substances that are in direct contact with each other. The better the conductor, the more rapidly heat will be transferred. An example of conduction heat transfer is the melting of ice cubes in your hand as heat transfers from your skin to the ice or the flow of heat from a hot object to a cold object in direct contact (figure 5).

As illustrated in figure 6, convection is the transfer of heat through gases or liquids from a warmer spot to a cooler spot. Radiation heat transfer at temperatures representative of building components, occurs in the long wave IR portion of radiation spectrum. Due to this energy distribution, radiation heat transfer is directly proportional to the surface emissivity in the long wave IR spectrum. A highly conductive material has a surface with low emissivity and thus reflects IR radiation well.

For example, interior building heat loss is minimized by surfaces that provide low emissivity and a highly conductive surface, as the heat flow from an interior warm wall flows to the exterior colder surface through conduction.

To reduce heat transfer via conduction, a coating must have a high insulating quality. The insulating capability of a material is measured with thermal conductivity (k). Low thermal conductivity is equivalent to high insulating capability. Other important properties of insulating materials are product density (ρ) and specific heat capacity (c).

In conclusion, coatings can reduce heat transfer caused by convection, conduction or radiation. The use of IR reflective pigments in an exterior paint system can prevent radiant heat transfer, providing a cooler exterior surface and less conduction heat transfer in the summer. Interior coatings that provide low emissivity can also reduce heat transfer from radiant heat loss in the winter months, as illustrated in figure 4, above.

| Issue | Mechanism | Energy Saving Approach |

| Solar heating in summer

(high air conditioning cost) |

|

|

| Interior heat loss in winter

(high heating cost)

|

|

|

Figure 7 – Summary of how coatings can provide energy savings

To learn more about solar reflective coatings, please read “Beat the Heat with Solar Reflective Coatings” by expert Ron Lewarchik

References:

- 9-4forham Wikispace

- Saving Energy

- Heat Transfer Slideshare, slide 14

- Natural Convective Heat Transfer

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

Is there any “paper” which shows (e.g. in a diagram”) and explains, what surface heat reduction to expect from a coating system containing heat reducting constituents, e.g. on timber Windows and uPVC windows coated e.g. coated black, dark brown, and/or dark slate

Ron, nice article. I like the graphics and this would probably be a good InfoGraphic article.

Hello Jorn,

Excellent question. The suppliers of these pigments have a number of articles on heat reduction through the use of IR reflective pigments by color. I would check with suppliers such as Heubach, Shepard and/or Clarient.

Ron Lewarchik