Even as work on 3D printing is only just taking off, scientists have already begun exploring a range of uses for 4D printing technology that should prove offer impacts in just as many applications, from the medical field to transportation and far beyond.

4D printing is an emerging technology similar to 3D printing (additive manufacturing), but adds the fourth dimension of time. Some industry commentators now prefer to use the term "3D printing and self-assembly."

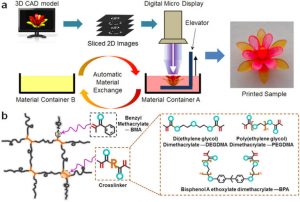

Using this technology, the manufactured products grow into their final form after exposing them in a particular environment (Fig 1).

Shape memory alloys using temperature changes to cause changes in material shapes have been around for many decades; 4D printing exploits them. Electro-active polymers, on the other hand, use catalysts that activate polymers with pressurized fluids, gases or even light. Other 4D printed structures are catalysed using moisture.

4D Printing: Solar Cells

According to a combined research team from Massachusetts Institute of Technology (MIT) and the Singapore University of Technology and Design (SUTD, Fig 2), solar energy may be one of the top two fields to benefit from 4D printing.

Complex 3D structures are printed with light in a proprietary process that programs them to return to their original forms in a matter of seconds as soon as their temperature reaches a certain “sweet spot.” The research has been published in the online journal Scientific Reports under the title, “Multimaterial 4D Printing with Tailorable Shape Memory Polymers“.Fig 3 illustrates the workflow for fabricating a multi-material structure based on a photo-curable shape memory polymer network.

Author Dr. Nicholas X Fang, MIT's associate professor of mechanical engineering, says that the materials can switch between two states – a harder state at lower temperatures and a softer state at higher temperatures.

"This opens up potential uses in biomedical devices, soft robotics, wearable sensors and artificial muscles," he says. “Other practical applications, include deployable aerospace structures, and shape-changing photovoltaic solar cells.” The latter are shown in Fig 4.

4D Printing: Medical Applications

The technology could also be used to create drug capsules that release medicine at the first sign of an infection.

“We ultimately want to use body temperature as a trigger,” says Fang. “If we can design these polymers properly, we may be able to form a drug delivery device that will only release medicine at the sign of a fever.”

Researchers say 4D printing technology could have additional medical applications such as stents that expand after being exposed to heat. The work derives from a project to develop high-performance 3D printed carbon fibre composites.

4D Printing: Transportation

4D printing pioneer Skylar Tibbits' team in MIT's Self-Assembly Lab is 4D-printing self-assembling shapes made of programmable carbon composites and custom wood grain. Notably, the Self-Assembly Lab partnered with Autodex software, high-end sports car maker Briggs Automotive Company, and flexible carbon composite maker Carbitex for a project.. Using programmable carbon composites, they designed a morphing car airfoil that operates non-mechanically.

According to an article in MIT Technology Review, Airbus is interested in similar programmable carbon fibre composites. Components and structures made of them could change shape in response to different environmental changes in temperature, air pressure, or other factors. They could replace hinges, or even motors and hydraulic actuators, making planes simpler and lighter in weight. Interestingly, Airbus mentions "morphing materials," as well as 3D printing, as a future technology that could be used in the Concept Cabin of its Concept Plane.

Carbitex's materials have various flexibility characteristics, such as floppy versus springy. The 3D printer adds these to materials that change flexible composites in specific ways in response to heat, light, or water. The Self-Assembly Lab team is developing software to simulate how these shape-changing materials will behave when printed onto different types of flexible composite materials.

Folding structures

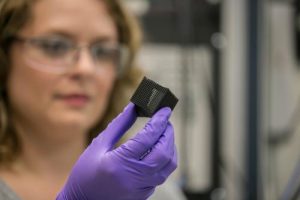

Meanwhile, researchers at Lawrence Livermore National Laboratory have 3D printed shape-shifting structures that can fold and unfold themselves, or expand and contract in size, when prompted by changes in electricity or heat (Fig 5, above).

The primary shapes they created were printed with shape-memory polymer inks developed by the team using a direct-ink writing 3D printing process. The ink is made from soybean oil and additional co-polymers, plus carbon nano fibers.

Similarly, a University of Colorado-Boulder team used an Objet Connex multi-material 3D printer to combine shape-changing materials that respond to heat and printed objects in one shape that changed their shape later, including a self-assembling cube.

References

- Multimaterial 4D Printing with Tailorable Shape Memory Polymers. Qi Ge, Amir Hosein Sakhaei, Howon Lee, Conner K. Dunn, Nicholas X. Fang & Martin L. Dunn. Scientific Reports 6, Article number: 31110 (2016)

- Shape-Shifting Carbon Composites Could Save Fuel

4D market research resources:

- 4D Printing Market Overview, Growth, Demand and Forecast Research Report to 2021. Published by 360 Market Updates

- 4D Printing Market - Global Trends, Market Share, Industry Size, Growth, Opportunities, and Market Forecast - 2015 – 2022. Published by Research Corridor

- Global 4D Printing Market 2016 Industry Analysis, Size, Share, Trends, Segment and Forecast. Published by 9D Research Group

Search for plastics by material properties

With Prospector's Property Search, search by properties to effectively and efficiently find the right plastics for your project.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

Thank you for the interesting article. When do you think 4D printing will become a commercial home product?

I don’t think this is a technology which will find its way into the domestic arena, unlike the likely trend of 3D printing. It’s in the research stages and the limit is likely to be niche industrial applications – in my opinion anyway!

Hii

I need a proto type made of

Something that will be

Wanted by millions

It also will be wanted and need in industrial realm

How do I proceed ??

Hi Linda,

Please send me details on [email protected] and I’ll try to advise!

Thanks!

Andy

4D printing is the greatest innovation in the manufacturing industry. There is such an application like a 4D printed valve, 4D printed shoes, $D printed pipelines will play an important role.