Smart coatings are based on smart materials, which change their properties in response to environmental stimuli. This results in functionality that is quite dynamic and, in some cases, mimics the responses of nature. This is called biomimicry, which comes from the Ancient Greek words βίος (bios), life; μίμησις (mīmēsis), imitation; μιμεῖσθαι (mīmeisthai), to imitate; and μῖμος (mimos), actor. The term was coined by Otto Schmitt in the 1950s. Smart coatings is such an important area of research that an entire conference is dedicated to it – Smart Coatings 2016 will be held in February 2016 in Orlando, FL.

Existing examples of smart coatings and materials include photochromic eyeglass lenses that darken in response to sunlight and hydrophobic coatings that repel water using a mechanism and structure similar to that of the lotus leaf.

There are many areas of interest and developing technologies, with arguably the highest level of attention being paid to self-healing coatings and materials, anti-fouling below waterline marine coatings and sensing materials. Let’s look at each of these three with respect to why they are of high interest, what they are, their applications, and some developing technological approaches.

Self-healing coatings and materials

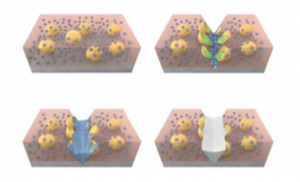

The concept of self-healing has been of interest for many years, but recently several breakthroughs have occurred in both traditional coatings, like those used for industrial applications, and in medical dressings, which are also coatings per se. Self-healing refers to the spontaneous formation of new bonds when old bonds are broken within a material. There are currently three main methods for self-healing restoration: intrinsic self-healing, vascular self-healing and capsule-based. [1]

For living organisms, the concept of self-healing isn’t a second thought. A person receives a cut or abrasion, and the body immediately begins to repair itself by sending materials to the damaged site. Hemostasis occurs first, which is the cessation of bleeding. Within minutes or even seconds, blood cells begin to clump together and clot, protecting the wound and preventing further blood loss. These clots, which turn into scabs as they dry, are created by a type of blood cell called a platelet. The clot also contains a protein called fibrin, which forms a net to hold the clot in place. Medical dressings have been developed that essentially do exactly the same thing. Hydrogels are common materials that have similar performance to new growth skin by forming a network.

Self-healing materials for traditional (paint) coatings typically don’t have this first step, since most coatings are solid and not liquid. However, the remaining steps in the self-healing of a wound are very similar to many emergent technologies. The more common system consists of an encapsulated resin and perhaps a corrosion inhibitor. When a cut occurs, the capsule breaks, releasing the resin and healing ingredients into the site. Another technology allows the abraded site to be externally heated so that the resin flows and levels and fills in scratches. This is called a “capillary” or “vascular” approach, since it mimics the body’s capillary vesicles.

The interest in self-healing technology is obvious. Currently, if an intrusive wound is identified in a coating surface, a field-applied touch-up is required. But if it is not noticed, it is a site for corrosion. A self-healing process does not require labor to repair a problem area.

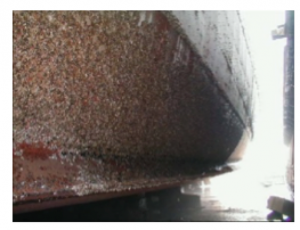

Anti-fouling below marine waterline

Ship bottom coatings have greatly evolved over the past 20 years. Marine organisms, such as barnacles and other flora and fauna, increase drag, which can result in 5-7% additional fuel consumption to overcome the friction versus a clean hull. In freshwater, zebra mussels continue to be a nuisance to water intake and discharge piping for potable water, power plants and other operations. Therefore, the reduction or elimination of organisms’ ability to adhere to surfaces is an object of great interest, as it is very expensive to take any downtime for cleaning.

There are several approaches that have been utilized to this end. Hydrophilic coatings have been used with cellulosic materials, which slough off slowly over time and minimally allow adherence. These are highly microporous and have a tendancy to swell. Hydrophobic coatings, on the other hand, provide a hard surface that is very difficult for anything to adhere to and are typically siliconated or fluorinated resins. The very low surface energy inhibits the adhesion of biological organisms. A newer approach utilizes self-assembly to inhibit adhesion.[2]

Sensing materials

There are many examples of sensing materials which result in a stimulus response. Probably 75% fall under the general heading of optoelectronics and piezoelectrical, but many other areas are gaining traction with new, innovative solutions.

Icing on transportation and power industry surfaces is problematic. An ingenious solution is an anti-icing coating that responds to surface icing by releasing antifreeze liquid. It consists of an outer porous superhydrophobic epidermis and a wick-like underlying dermis that is infused with antifreeze liquid. It has been found to be highly effective in both performance and cost.

There have been several DoD programs targeted at chemical agent threats. Anthrax being the primary threat, some solutions have included a multi-solution approach. Anthrax is a very difficult material which is only deadly with germinated spores. And the spores are nearly-impossible to destroy. One solution includes a hydrophilic coating that retains water and germinates anthrax spores on contact. The coating itself is also hydrophobic, making it more difficult for spores to adhere to it and easier to wash off. And a novel biocide for anthrax was included to kill the anthrax once the spores germinated.[3]

Last, there is a series of materials that have been developed and are under evaluation that are used in coatings and can sense corrosion. Rather than requiring expensive and time-consuming inspections or relying on life-cycle analysis (LCA) historical data to predict failures, the sensors provide real time data to monitor the health of the metal substrate.[4]

In conclusion, the area of SMART materials and coatings is rapidly growing and is an exciting technology platform. There are several excellent books and a handful of conferences that address the subject.

References:

[1] Thanawala, Karan; Development of Self-Healing Coatings, IITB-Monash Research Academy.

[2] Christopher Ober; Ambiguous Surfaces: Antifouling and Fouling Release Coatings that Use Self-assembly to Inhibit Bioadhesion, SMART Coatings 2016

[3] US20080050419A1; Self-decontaminating Surface Coatings and Articles Prepared Therefrom

[4] Fritz Friedersdorf, Ph.D., Smart Sensors for Aircraft Corrosion Monitoring

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

What is the expected service life of anti-icing smart coatings?

Greg, it is too early to tell at this point, since the earliest efforts were only 3 years ago. There is actually a talk at SMART 2016 next month from Fraunhofer.