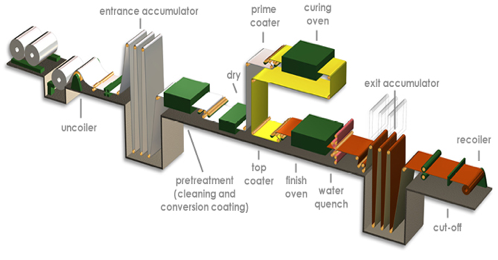

Over 800 million tons of coil-coated metal are produced and shipped annually in North America alone. Coil coating (see Diagram I) is a very efficient way to produce a uniform, high quality, coated finish over metal in a continuous automated fashion. Coil coating is also referred to as pre-painted metal, because the metal is painted prior to, rather than after, fabrication.

Over 800 million tons of coil-coated metal are produced and shipped annually in North America alone. Coil coating (see Diagram I) is a very efficient way to produce a uniform, high quality, coated finish over metal in a continuous automated fashion. Coil coating is also referred to as pre-painted metal, because the metal is painted prior to, rather than after, fabrication.

In the coil coating process, the metal coil is first unwound, cleaned and pre-treated, applied on a flat continuous sheet, heat cured, cooled and rewound for shipment. At the fabricator, it is then cut to the desired size and formed into its finished shape. Versus most other application methods, coil coating efficiency is nearly 100%. Application is at very high line speeds as modern coil lines can run at speeds as high as 700 feet per minute and cure the applied paint in 15 – 45 seconds. As opposed to a spray-applied coating, for example, a coil-coated, formed surface offers uniform film thickness rather than the thicker films on edges, corners and bends that is more typical of spray-applied coatings.

Topcoats are applied by reverse roll coat in which the applicator roll travels in the reverse direction of the strip and thus provides a smoother film with fewer defects. Primers and backers are normally applied by direct roll coating. Some lines also apply coil coatings using an extruder or via a solid block of paint with a softening point such that it can be applied smoothly when heated.

The types of paint curing employed in the coil industry include thermal, infrared, induction and UV cure. By and large, the vast majority of coil coatings are cured using gas-fired ovens. Accordingly, the remaining portions of this article will focus on thermal-cured coil coatings. Coil primers and backers are normally applied much thinner than spray-applied liquid or powder coatings, dip or electrocoat paints. Applied primer dry film thicknesses are normally in the range of 4 – 6 microns in thickness, whereas topcoats are normally applied to provide a dry film thickness of 18 – 20 microns.

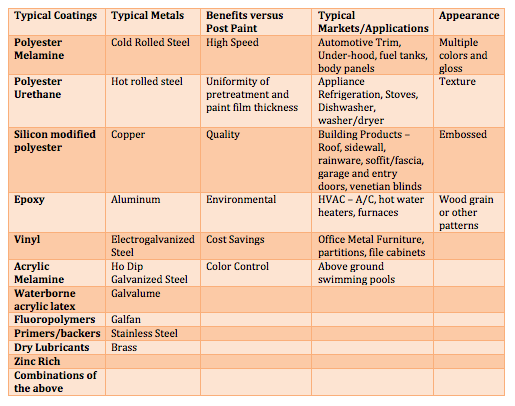

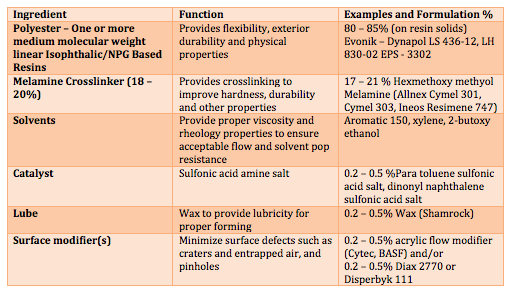

Special consideration when formulating coil coatings include adjustments in the resin technology, crosslinking, solvent system, catalyst, surface modifiers and lubricants to accommodate proper cure, flow and leveling, and minimization of surface defects. Once cured, coil coatings can offer excellent handling, physical, chemical and environmental properties. From a paint usage standpoint, polyesters make up the bulk of coil coatings. Table II details typical materials utilized in a polyester coil coating.

In summary, coil coating technology has grown more rapidly than more conventional application technologies due to a variety of benefits that include cost savings, versatility, environmental, performance and quality issues.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

I’am Thanaporn Pleemat from SEKISUIJISHI PLAMETAL (THAILAND) CO.,LTD

I interested in your product and I would like to request quotation for color coated aluminum detail as below.

Hi Thanaporn,

Prospector does not supply products, but you can search for them and contact suppliers via our platform. Start here: ulprospector.com.

Thanks!

Angie

Content Manager, Prospector Knowledge Center