JEC Exhibition, Paris, 10-12 March

Unusually, the main talking point at what turned out to be the last-ever JEC Europe (Porte de Versailles, Paris, 10-12 March 2015) was the show itself. Signalling the ever-increasing importance of composites in contemporary manufacturing, the exhibition is deemed to have out-grown its spiritual home, and is moving to the other side of Paris. From 2016 (8-10 March) the show will be at the Paris Nord Villepinte fairgrounds and renamed JEC World. Justifying the name change and the move from the south to the north side of France’s capital, Madame Frédérique Mutel, JEC Group President & CEO says “With the number of programmes, manufacturers and visitors, 58,000 sqm are no longer enough. The site is close to infrastructures like the Roissy Charles de Gaulle airport and the Roissy TGV high-speed train station, giving our international visitors easy access to the event.”

Moving to more technical matters, I will be reviewing developments in carbon-fibre reinforced plastics in a couple of months, with particular emphasis on thermoplastics, so will focus here on other themes.

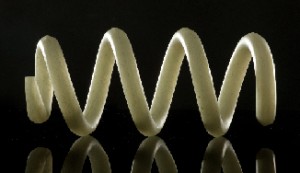

Coil springs

Amongst the other items that caught my eye were the glass fiber reinforced plastic (GFRP) coil springs manufactured by Sogefi and launched in serial production on the European car market at the end of 2014. Glass fiber specialist, Owens Corning, customized a reinforcement especially for Sogefi’s project.

Amongst the other items that caught my eye were the glass fiber reinforced plastic (GFRP) coil springs manufactured by Sogefi and launched in serial production on the European car market at the end of 2014. Glass fiber specialist, Owens Corning, customized a reinforcement especially for Sogefi’s project.

Audi is the first car manufacturer in the world to roll out the new technology in mass production on the A6 Avant 2.0 TDI ultra. The new springs can be mounted on cars and light commercial vehicles with no change to the suspension system, and will provide a weight reduction of approximately 4.4kg, compared to springs made from steel. Replacing steel by materials that are not subject to corrosion also guarantees a lower noise level.

Simulation and analysis

Simulation and analysis are increasingly key to efficient composite design. ESI Group launched “Composites Simulation Solution 2015”. In reality, this is a suite of three different software modules: PAM-Form, PAM-RTM and PAM-Distortion.

PAM-Form simulates preforming of dry textiles or thermoforming of pre-pregs made of thermoset or thermoplastic resins. Processes covered include stamping, rubber pad forming, thermoforming and diaphragm forming. PAM-Form can correct and optimise process aspects, such as kinematics, temperature and pressure cycle, clamping conditions and forces, initial flat pattern. Because all of these results are available at ply level, rather than only at laminate level, it provides for, as an example, the prediction of internal wrinkles, as well as thickness defects, bridging, strains, shear and in-fiber stresses and fiber orientation.

Processes that can be modeled with PAM-RTM include mold pre-heating, Resin Transfer Molding (RTM), Vacuum Assisted Resin Infusion (VARI), Compression RTM (C-RTM) and curing thermoset parts. Defects such as dry zones or porosity can be corrected by virtually fine-tuning parameters including the location and shape of the injection gates, the vents and vacuum ports, the position and type of flow media, the heating of the mold and parameters related to the curing cycle.

Processes that can be modeled with PAM-RTM include mold pre-heating, Resin Transfer Molding (RTM), Vacuum Assisted Resin Infusion (VARI), Compression RTM (C-RTM) and curing thermoset parts. Defects such as dry zones or porosity can be corrected by virtually fine-tuning parameters including the location and shape of the injection gates, the vents and vacuum ports, the position and type of flow media, the heating of the mold and parameters related to the curing cycle.

PAM-RTM can deal with extremely large numerical models using shell or solid elements. This is essential when addressing both the large component size required in the wind industry and the extreme detail of small components for the automotive industry.

PAM-Distortion is used to compute residual stresses and geometrical deformations, such as spring-in and warping, induced by the manufacturing process. It accounts for strains generated by the modification of material properties due to the phase transformations during curing. It can generate a compensated mold, based on computed distortions in order to obtain a final part geometry within the specified tolerance.

Materials data

Brussels-headquartered multinational Solvay also focused on analysis of composites. The company has included 13 of its advanced polymer grades in the latest release of the Digimat platform, the materials database and simulation tool from E-Xstream Engineering, a long-term partner of Solvay. Both companies were exhibiting at JEC. Digimat offers capabilities for computer design and simulation of fiber-reinforced composite parts.

The 13 new additions from Solvay’s portfolio are from four families:

- Amodel polyphthalamide (PPA)

- Ixef polyarylamide (PARA)

- Veradel polyethersulfone (PESU)

- Ryton polyphenylene sulfide (PPS).

Grades from Solvay’s AvaSpire polyaryletherketone (PAEK) and KetaSpire polyetheretherketone (PEEK) product lines were added to the Digimat-MX database in 2013. Omnix HPPA and heat-stabilized grades of Amodel PPA are expected to be added in the future.

More from JEC (and elsewhere) over the next two months.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

Leave a Reply or Comment