By Protomold – Nobody’s Faster In The Short Run.®

Normally, when nature produces polymers, they are strings of protein like keratin or polypeptides. Now, however, with help from companies like NatureWorks LLC, a subsidiary of Cargill, starch from corn is being turned into a different kind of polymer: plastic. Unlike typical plastics, however, this one is biodegradable.

|

|

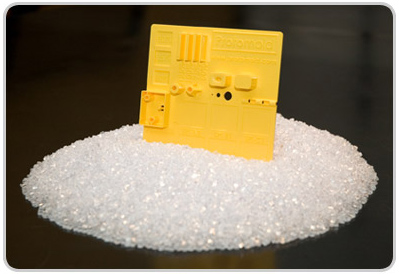

Fig. 1 – Corn-based Biodegradable resin pellets used for injection molding to create plast parts.

|

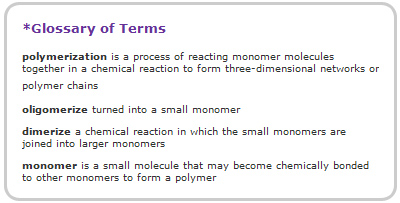

The multi-step process begins with the transformation of starch, by hydrolysis, into the sugar dextrose. Dextrose, in turn, is fermented to produce lactic acid. Lactic acid cannot be directly polymerized it is first oligomerized and dimerize to produce a lactide monomer from which the polymer polylactic acid can be made*. The result, sold under the brand name Ingeo™, is a biodegradable thermoplastic made entirely from renewable resources. The process turns about 2.5 pounds of corn into a pound of plastic. (*See Glossary of Terms below for polymerized, oligomerized, dimerize, and monomer definitions.)

The resulting resin is suitable for applications that might otherwise call for polyolefins, polystyrene, or cellulosic resins. According to the manufacturer, Ingeo can be clear or opaque and flexible or rigid. It offers gloss and clarity similar to that of polystyrene, tensile strength and modulus comparable to hydrocarbon-based thermoplastics, and is recommended for packaging applications. Unlike conventional plastics, however, it is biodegradable and can be broken down using commercial composting methods. Technical datasheets for the resin can be found at the manufacturer’s web site, www.natureworksllc.com.

Protomold has run Ingeo resin — NatureWorks 3051D — in small quantities with satisfactory results. The resin can be selected by your account manager as a special order option.

Keep in mind the selection of the proper material is crucial to your part production. Designers should consider the mechanical characteristics, molding properties, and cost of the resin used. Application-specific requirements will always drive the need for particular material properties like tensile strength, impact resistance or ductility. As you may already know, successful designs for injection molded parts are also built on an understanding of process-related issues such as the ability to fill the mold, tendency to flash, ease of part ejection, and the potential for warp, sink or void creation.

In short, if you are looking for biodegradable injection molded parts, Ingeo brand PLA may be your solution. Be rest assured that there’s plenty of it available; if the existing supply should get used up, we assume that the folks at Cargill will just grow more.

|

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.