By Stephane Morin, Alliance Polymers & Services, LLC

Before TPEs (thermoplastic elastomers), there was thermoset rubber. But there was a need for a better type of product – one that could increase part production (lowering cycle times), offer lower weight, be easily colorable, be soft or rigid, be recyclable, be produced over other materials in a two shot process (overmolding), and contribute to lower part costs.

Enter TPEs in the 1970’s on a mass scale, soon to be followed by other soft elastomers that soon fell under the general category of TPEs – TPOs or thermoplastic olefins, TPVs or thermoplastic vulcanizates, TPUs or thermoplastic polyurethanes and dozens of new grades that were and are simply ‘alloyed’ products comprised of different components. And, soon thereafter were grades that could not only be injection molded, but also extruded, blow molded or thermoformed.

New Compounds, New End Products

Products started appearing on the market with a new look and feel, enabling manufacturers to upsell their wares to appeal to new markets – the venerable power drill comes to mind – the same basic drill innards over the years, but ‘reintroduced’ with new, visually-appealing grips. And then came new and better products for goods such as sporting equipment, automotive seals and hoses, medical goods, appliance parts, window and glazing seals, wire and cable applications and hundreds of other products in dozens of markets. Thanks to TPEs, they not only looked better and could be processed better, but they performed better and offered a variety of textural and finishing options. Depending on the application and the product, they were softer or harder, more resistant to chemicals and oils, more durable, able withstand far higher and lower temperatures, and ultimately would and could last longer.

The advent of TPEs enabled designers, marketers and manufacturers to offer products with much broader options for design, including improved grip with built-in ergonomics, improved sealing, living hinges, noise and/or vibration damping and protection, and reduce scrap, among others. This was combined by improving product development cycle times, speeding up production cycle times, reducing materials usage and generally decreasing production costs.

More recently came bonding grades which maximized the potential of overmolding technology. This reduced or eliminated the need for adhesives or other mechanical interlocks to combine different materials, including grades that could be bonded onto many other polymers as well as many metals (and in fact, replaced many metals). With the ability to overmold onto a variety of materials, components now can easily and cost-effectively produced/molded into soft/hard material combinations, while all the while ensuring outstanding performance.

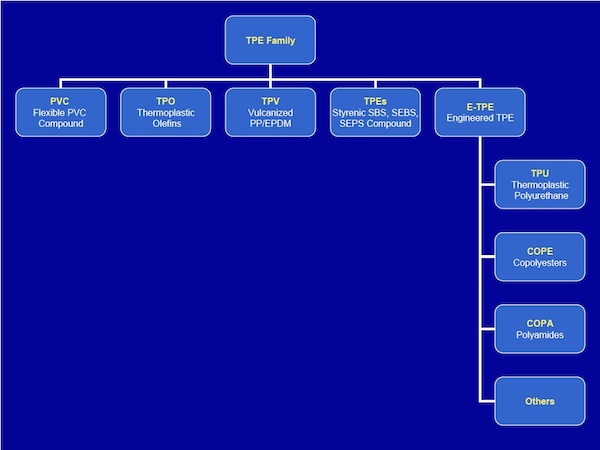

At the present time, there are numerous classes of TPEs. These are:

• Polyurethanes (TPU)

• Styrenics (TPE-S)

• Copolyesters (COPE)

• Polyamides (PEBA)

• Polyolefin Alloys (TPV)

• Polyolefin Blends (TPO)

The accompanying chart will give potential users an indication where each class is best suitable for applications depending on prince and performance.

Which TPE to Use?

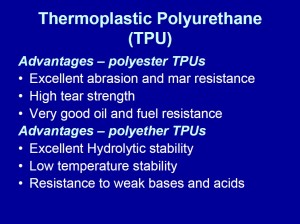

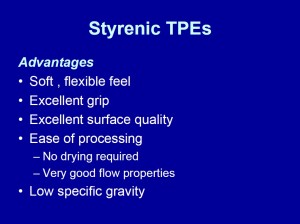

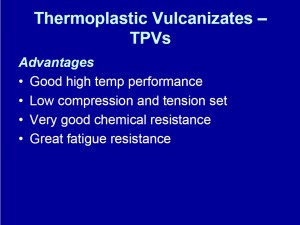

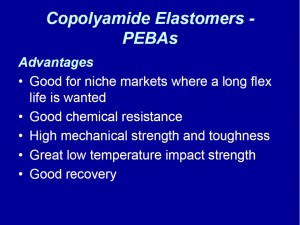

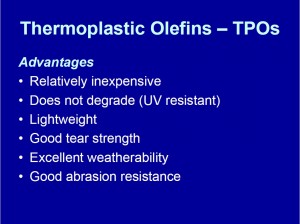

Below are listed the advantages of each class of TPE. Using these guidelines, potential users can quickly and accurately narrow the type of soft elastomer best suited for their application:

Producers of TPEs are being pressured to not just meet product end use specifications, but to exceed them. While larger TPE producers are inclined to want to sell off-the-shelf grades, many suppliers and distributors, especially smaller independent ones, are more inclined to offer grades that precisely match or exceed the needs of the finished product. Thus, the designer, marketer or OEM that wants to get full value out of a TPE, should look to the supplier that can offer a full range of technical services.

Designers and manufacturers who haven’t yet “caught on” to the inherent short and long term benefits of TPEs are missing out on compounds that are expected to continue to grow in usage some 6% or more per year, with an expected total usage worldwide of more than 13 billion pounds. With pressures to not only cut costs and speed up design-to-part cycles, designers and at the very least, automotive OEMs and Tier One suppliers can benefit by offering components that are lighter in weight, improve fuel economy, enhance performance, reduce system costs and improve recyclability. Newer flame retardant grades make products safer and less hazardous to the environment.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.