The plastics market has numerous methods to assist in identifying incoming materials like the burn and sniff test and density tests. They’re time consuming, not always the most practical, and most end up destroying the sample. These tests also create many challenges when trying to quickly, and reliably identify plastics, but there are alternative methods available that are safer and faster. With several growing concerns in the plastics market, including phthalates in children’s toys, a quick dependable option is becoming a necessity.

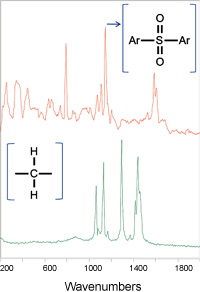

The RAPID•ID plastics identifier uses Raman spectroscopy to accurately identify differences in plastics in a matter of seconds. A Raman spectrum displays characteristic peaks that are related to specific chemical groups. For example the flame color and odor generated when a material is burned are associated with these same groups. A polysulfone plastic will produce a sulfur odor when burned. The Raman spectroscopic signature corresponding to the odor is the 1148 cm-1 peak due to O=S=O symmetric sulfone stretching. This demonstrates how a Raman spectrum, just like the sniff test, provides answers to correctly identify a material, Figure 2.

Here are two helpful case studies of how the RAPID•ID can simplify your process:

| Case Study #1 In today’s market place efficiency and waste means the difference between meeting goals and losing business. In the CD and DVD manufacturing business fast throughput is a must. When receiving raw material used in the manufacturing of the CD and DVD components it is vital to be able to check 100% of the incoming materials. The Rapid-ID provides you the tools to inspect your raw materials. For example, some polycarbonate samples were confiscated by customs officials. To the naked eye they look the same. To the Rapid-ID the optical grade polycarbonate is easily identified with a clean clear spectrum and the counterfeit or non-optical grade polycarbonate has a high background which is used to determine the grade of the polycarbonate as seen in Figure 3. |

Figure 3: Optical grade polycarbonate and counterfeit polycarbonate. |

| Case Study #2 Polyvinyl chloride (PVC) is a common polymer used in many different consumer products. PVC is softened, or rubberized with the addition of plasticizers in the form of phthalates at different concentrations. As the products age phthalates begin to leach out into their surrounding environments. Because of this several countries have banned the use of some phthalates in consumer products. With this ban there is a need for fast reliable screening test that can identify the presence of phthalates.The fixed Raman systems are more rugged and easier to operate yielding information with out difficult adjustments, making them ideal for field portable systems. It has been shown that FT-Raman can be used to analyze phthalates in plastic as an identification tool and as a quantitative tool.1 But most FT-Raman systems are expensive and difficult to use in the field setting such as at a port of entry. With the development of smaller dispersive Raman spectrometers Raman spectroscopy is no longer confined to only research and development but it is now used in different industrial capacities ranging from process analytics to raw material identification.The Rapid-ID can be used to test 100% of the incoming raw materials before they are unloaded from the truck or shipping container. Figure 4 demonstrates the portable Raman’s ability to distinguish between different phthalates. The ability to make fast accurate quality control decisions allows your company to meet the efficiency goals set by the demands of your customers and save thousands of dollars in lost time and/or repairs to manufacturing equipment.With the selectivity that Raman exhibits it is a perfect tool for qualitative analysis of consumer goods. Raman analysis of a flexible PVC toy was performed showing the presence of phthalates as seen in Figure 5. The 1600 cm-1 region in the Raman spectrum indicates the presence of the phthalates. This can be used to quickly determine if further testing is required for the consumer goods, reducing the amount of work load in the laboratories.1 T. Norbygaard and R. W. Berg, Appl. Spec. 58, 412 (2004). |

|

|

Figure 4: Raman Spectra of 6 phthalates showing the characteristic bands associated with the phthalate group. |

Figure 5: Qualitative Raman analysis of consumer toys. |

For more information on the Rapid-ID and how it can help you, view the Rapid-ID video below for industrial applications or visit the DeltaNu website at www.intevac.com | sales@deltanu.com | 866-301-6328

Related links

Eliminate Costly Misidentification of Similar Plastics | Take Control Over Quality & Costs | Plastic Material Identification – Raman Spectroscopy

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.