This is both a summary and an update on recent articles or webinars on fire retardants/fire resistance available through UL Prospector Knowledge Center. Wally Kesler’s post was in July 2018[i] and recent webinars were that were given by WEVO-CHEMIE GmbH in April 2021[ii] and Lubrizol in December 2020[iii]. It is suggested that readers review all three articles since they are very thorough in their explanation of types of materials used, particularly Non-Halogenated Flame Retardants (NHFR) and the certification for their use in applications of fire protection appropriate for the end-use. Different organizations test and certify fire retardant coatings, not dissimilar in the way tests differ between ANSI, ASTM, ISO and DIN.

This is both a summary and an update on recent articles or webinars on fire retardants/fire resistance available through UL Prospector Knowledge Center. Wally Kesler’s post was in July 2018[i] and recent webinars were that were given by WEVO-CHEMIE GmbH in April 2021[ii] and Lubrizol in December 2020[iii]. It is suggested that readers review all three articles since they are very thorough in their explanation of types of materials used, particularly Non-Halogenated Flame Retardants (NHFR) and the certification for their use in applications of fire protection appropriate for the end-use. Different organizations test and certify fire retardant coatings, not dissimilar in the way tests differ between ANSI, ASTM, ISO and DIN.

The definition of a fire-retardant coating is not clear-cut and often confused or interchanged with the term “fire-resistant,” but there is a distinction. A fire-resistant coating doesn’t ignite or support flame when an ignition source is applied, while a fire retardant coating protects the substrate from burning. In performance-based testing, the mechanism of protection is secondary to the final result.[iv]

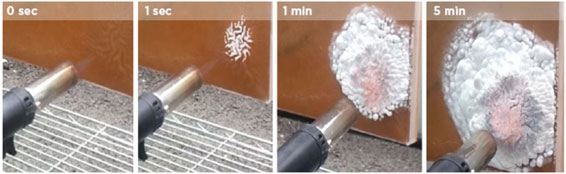

In addition, the term “intumescent” is associated with fire-resistant paints, and that term is sometimes misunderstood. Intumescent is swelling up when heated, thus protecting the material underneath or sealing a gap in the event of a fire. Coatings are generally certified to protect the substrate for one or two hours, as per UL 263, CAN/ULC-S101 and ISO 834. Structural steel is the most protected material, but protection can include other materials such as sheet metal, sheetrock, composite panels and interior woods. The intumescent products and operations are audited and listed by a certified third-party laboratory to ensure that the intumescent products perform as expected to ensure building fire safety as per ASTM E119.

To achieve the proper fire rating, the coating must be applied to the specific Dry Film Thickness (DFT) that each company specifies in their technical bulletin, depending upon effective thickness. The Wet Film Thickness (WFT) can be applied similarly to achieve rating requirements. Dry film thickness relates to wet film thickness based on solids and loading.

Use of fire retardant coatings usually requires certification that the substance provides the level of fire protection claimed in its attributes and for its use. Depending on where the coating is used, different regulatory bodies certify its application, and within the regulatory body, applications differ due to smoke density, oxygen index and smoke toxicity. Generally, the coatings are policed by the National Fire Protection Association (NFPA) for construction, American Society for Testing of Materials (ASTM) overall for the test methods; corporate and commercial guidelines for aviation; government for transportation; the Federal Aviation Administration (FAA) and railway components.

Fire retardants and certification have to be considered together. Certification of fire retardant materials is important in their use. For example, in an enclosed area, such as a submarine, airplane, etc., smoke or a toxic material released even during the flame being extinguished is not acceptable.

Fire resistance is evaluated by affecting an ignition source under controlled conditions and measuring one or more of the following performance parameters. As an example, a test might include a primer and paint over sheetrock, and a flame applied to an area, and the following tests would be evaluated, if applicable.

- Heat Release uses calorimetry to determine peak and average energy produced by combustion of the test sample.

- Smoke Density is an indicator of the optical density of the smoke generated from the burning test sample.

- Smoke Toxicity requires specific chemical analysis for targeted toxic components in the smoke generated during combustion.

- Flame Spread measures the extent of the burned surface from the original site of ignition.

- Self-Extinguishing is defined as the ability to extinguish a flame after the ignition source is removed from contact with the test sample.

Fire retardant materials – compositions

Various factors affect which combination of materials to use. As with most things, cost and performance are the overriding factors. Regulations such as REACH and RoHS can exclude non-conforming materials regardless of any performance or economic advantages and must be the first consideration when choosing a fire retardant.

The planned purpose and required performance standards are the next screening measures, not only from the perspective of what fire retardant materials to use but also how fire retardants can affect other physical properties of the coating or composite material in its end-use.

If you want to find out about the types of materials that are used for fire retardants, the non-webinar UL Prospector Knowledge Center article is an excellent place to start. As far as safety with fire retardants, the following common-sense steps should be taken:

- Keep dust levels down by wet mopping and vacuuming with a high-efficiency particulate air (HEPA) filter to help remove contaminants from your home.

- Wash your hands and those of your children often. Hand-to-mouth contact exposes people to flame retardants.

- When purchasing new products, try to purchase baby products and furniture filled with cotton, polyester or wool, instead of polyurethane foam.

- Reduce dust by having a good ventilation system in your home.

Summary

Choosing specific fire retardant chemistries not only depends on the targeted performance objectives but also on regulations that may prohibit certain compounds. The most effective fire retardant coatings often rely on a combination of compounds; synergy within that combination plays an important role in the efficacy of the final product.

Other information:

- Flame Retardants Fact Sheet (nih.gov)

- Home – National Toxicology Program (nih.gov)

- Consumer Fact Sheet on Flame Retardants | US EPA

[i] Formulating fire retardant coatings: answers to your burning questions (ulprospector.com)

[ii] WEBINAR: Fire-retardant polyurethane, epoxy and silicone resins (ulprospector.com)

[iii] WEBINAR: Sustainable, Non-Halogenated Flame Retardant TPU’s (ulprospector.com)

[iv] Formulating fire retardant coatings: answers to your burning questions (ulprospector.com)

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

I question the accuracy and value of the article in teaching what the terms Fire Retardants, Fire Resistant and Intumescent really mean.

The terms “fire retardant” and “fire resistance” are defined terms in ASTM E176, Standard Terminology of Fire Standards and in ISO13943, Fire safety – Vocabulary. Further, UL Guide Information BMQX describes Fire Retardant Coatings, UL Guide Information CHPX describes Sprayed-applied Fire-resistive Materials and UL Guide Information CDWZ describes Intumescent Fire-resistive Materials.

The article does not include references to any of these five documents and, at times, is not in agreement with the concepts expressed in the references. It is suggested after review of the references, the article be revised and republished to compliment the references.

Thank you for your comments. If you have followed UL, you would see that the articles are for general information and are limited by content. There are generally links included which bring the reader to deeper information. Being as you seem to be an expert, it behooves me to understand why you would be interested in reading this. But I appreciate your comments and your references to the other documents. As far as revision, I’m sure it will be updated sometime in the future. Kindest regards

Hi All

I am searching to purchase intumescent paint for HEA 300 columns.

It is for a food industry plant.

I need supplier contacts in Europe

Thanks

We don’t normally recommend products as part of the knowledge center. I think if you were to search by European suppliers of intumescent coatings on any one of the number of sites, you will find what you need.