Many optical devices like photocopiers, printers, and monitors depend on the light-based surface change in azobenzene polymer film. It has a surface that can change shape when exposed to light. This makes it potentially valuable in devices like TV screens and solar cells. Azobenzene film can also act as an “actuator” (that part in a device that moves other parts) in nanomachinery.

Many optical devices like photocopiers, printers, and monitors depend on the light-based surface change in azobenzene polymer film. It has a surface that can change shape when exposed to light. This makes it potentially valuable in devices like TV screens and solar cells. Azobenzene film can also act as an “actuator” (that part in a device that moves other parts) in nanomachinery.

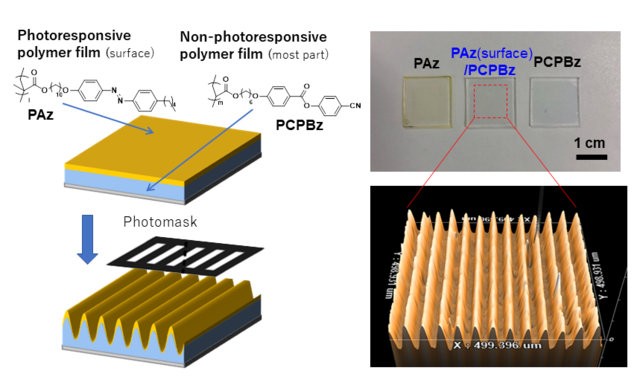

Now, scientists have shown that just a thin, surface layer needs to be light-sensitive, opening up ways to reduce production costs and revolutionize its use.

What causes the shape-shifting movement? A group of scientists led by Dr. Takahiro Seki of Nagoya University, Japan, have now published their findings in the journal Scientific Reports.

As their inspiration, they cite a well-studied phenomenon called Marangoni flow: differences in “surface tension” (the property by which the particles in the outermost layer of liquids are always attracted inwards, creating a boundary for the liquid) cause many soft, plastic films to move in a peculiar pattern. A familiar example of this phenomenon is the formation of “wine legs” or droplets of liquid evaporating and streaking down the surfaces of wine glasses.

They decided to test whether ultraviolet light-triggered changes in the surface tension of azobenzene plastic film, and whether those changes resulted in the film moving. Firstly, they chose to cover the azobenzene film with a very thin top layer that was light-sensitive, then exposed this film to UV radiation. Next, they did the same with film that was covered in a top layer unresponsive to light. They found surface structural changes in the film with a light-sensitive top layer, but not in the film with a light-insensitive top layer. “This is the first time anyone has demonstrated that only the light responsiveness of a very thin nanometre-level layer is needed for azobenzene-containing film to alter its surface morphology under UV,” says Seki.

Movement of the material is not dependent on light polarization – the direction in which light waves travel. If it were, that would suggest that there is another force on the molecular level affecting the whole film. Instead, Seki concludes that it is the changes in chemical structure at the surface induced by the UV radiation that changes surface tension, inducing movement to the top of the film.

Describing the wider ramifications of their results, Seki states: “We are only at the cusp of developing this discovery onto an industrial scale, but you can imagine how needing only a very small amount of light-sensitive material can reduce costs.”

Reference: Photo‑triggered large mass transport driven only by a photo-responsive surface skin layer, Scientific Reports 29 July 2020, DOI: 10.1038/s41598-020-69605-8.

Search using over 600 property filters with Prospector Advanced Tools. Upgrade to the Plus plan to start your detailed search today!

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

Leave a Reply or Comment