Tailored Fibre Placement (TFP) technology allows the fabrication of preforms tailored for specific composite components or reinforcements. Applications range from highly accelerated lightweight parts for industrial robots or blades for compressors up to CFRP aircraft parts.

Tailored Fibre Placement (TFP) technology allows the fabrication of preforms tailored for specific composite components or reinforcements. Applications range from highly accelerated lightweight parts for industrial robots or blades for compressors up to CFRP aircraft parts.

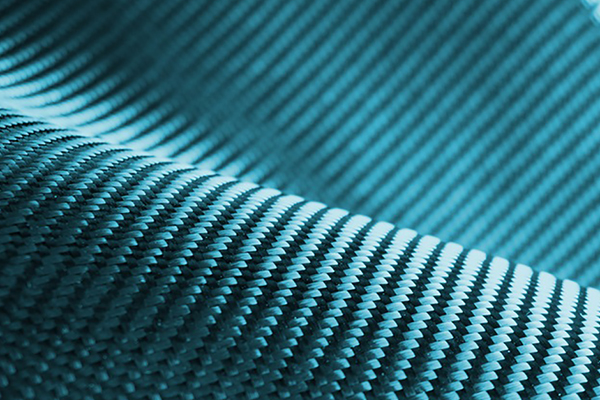

A special characteristic of continuous fibre reinforced composites is their anisotropic properties. Maximum properties exist only along the fibre direction. Even small differences between fibre orientation and angle of maximum stress reduce the load carrying capacity enormously. Finite element analysis can be used to generate a plot of the principal stresses. With TFP, designers attempt to arrange the fibres in such a way that they follow the stress field in the composite component under end-user conditions, whereas with conventional semi-finished reinforcement techniques, such as fabrics, multiaxial warp knitted fabrics and braids, this is only partially possible.

TFP was introduced in the early 1990s by IPF Dresden. At the beginning, handmade stitched reinforcement structures (preforms) were manufactured with a curvilinear pattern. An adaptation of this method to industrial embroidery machines, by using the sewing capabilities of those automates, was implemented in the mid-90s. The technology was named Tailored Fibre Placement (TFP), which describes the variable axial near-net-shape fibre placement capabilities. Nowadays, TFP is a well-established though not widely applied textile technology for dry preform manufacturing.

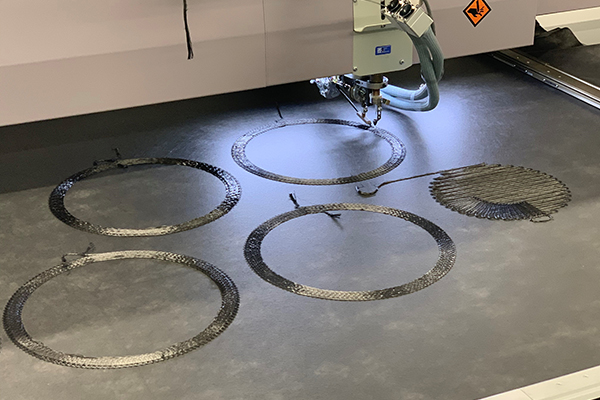

Now, UK structural composites specialist Carbon ThreeSixty is to announce at the JEC World Exhibition in Paris the recent installation of an in-house Tailored Fibre Placement (TFP) cell which will deliver complex composite products three times quicker than traditional methods whilst also reducing waste by up to 90%.

The new automated facility – the only commercially accessible machine of its type in the UK – uses high precision free-form fibre placement to enable greater design freedom, improved repeatability and creates the opportunity for multiple complex design configurations. Intended for high utilisation operation, it can produce up to 100 metric tonnes of composite preforms per year.

“We specialise in the design and out-of-autoclave manufacture of highly stressed novel composite structures,” said Ed Allnutt, Managing Director of Carbon ThreeSixty. “The TFP cell enables the production scale-up of our defence wheel products, whilst significantly contributing to ongoing R&D activity with clients in other sectors. Such challenging structures are inherently complex, and for true weight, stiffness and strength optimisation the reinforcing fibres must be placed to run in specific orientations, so for us TFP was the obvious solution.”

Carbon ThreeSixty invested in the TFP machine in autumn 2019, following a successful trial of the technology at the UK’s National Composites Centre (NCC) in Bristol. That trial directly contributed to Carbon ThreeSixty securing ongoing R&D and pilot production projects with a global land defence OEM.

Based on embroidery machinery used in the garment textile industry, the machines have been adapted to deposit and stitch fibre roving material onto a base material. Roving material, mostly common carbon fibres, from about 3,000 up to 50,000 filaments can be applied. The preform is produced continuously by the placement of a single roving. Currently, up to 800 stitches per minute can be achieved. The base material can be a 2D-textile such as woven or non-woven fabric or a matrix-compatible foil material for thermoplastic composites. A variety of fibres, including carbon, glass, basalt, aramid, natural, thermoplastic, ceramic fibres and metallic threads can be applied and combined within one preform.

Using automation, TFP enables fibres to be accurately positioned onto a variety of backing materials in the exact orientations required and secure in place with a fine thermoplastic polymer fibre. These bespoke preforms are then placed into precision RTM closed moulds, impregnated with high performance resin and cured, giving rise to a highly engineered end-product.

“Thanks to TFP when it comes to shape, we are able to make products that were previously out of reach using traditional preforming methods, which are labour intensive, time consuming, and less accurate with poorer repeatability,” Allnutt continued.

Key advantages of TFP technology

- Net-shape manufacturing reduces costs and waste

- Automatic deposition ensures high accuracy and repeatability of amount orientation of fibres

- TFP machines with multiple heads can be applied to improve productivity

Reference

Leibniz Institute of Polymer Research Dresden (IPF)

https://www.ipfdd.de/en/organization/departments/institute-of-polymer-materials/mechanics-and-composite-materials/fields-of-work/complex-structural-components/tailored-fiber-placement-principle/

* The world will have to wait a little longer to see this development, as the JEC Exhibition has been postponed until May as a result of the coronavirus outbreak.

https://www.jec-world.events/COVID19_JEC-World-Official-Statement_February-24.pdf

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

Does anyone provide a service where a thin flexible belt can be built on a filament-winding type machine, but with thermoplastic fiber or tape as the starting material?

Hi, Vis:

This is a useful article with a list of filament winding suppliers:

https://www.compositesworld.com/articles/a-filament-winder-buyeramp39s-guide

I hope you find it helpful!

Thank you,

Andy

Hi Vis, Sorry only just seen this comment. Please feel free to contact Carbon ThreeSixty Directly for more information.

Wonderful information, thanks a lot for sharing kind of content with us. Your blog gives the best and the most interesting information. I wonder if we can gather such practical information about tailored fibre placement. Great one!!